Blog

Introduction

Waterproofing is a process of making a structure water-resistant or impervious. Waterproofing plays an essential part in any household. It prevents water from seeping into the house and thus causing major problems such as mold growth and property damage. Toilet is a humid area, which involves water and plumbing work that will cause high moisture and humidity, hence waterproofing of toilet is very important and inevitable. Waterproofing a toilet involves applying a physical barrier to the surface such as the floor and wall to avoid the water from seeping in the structure. The application of waterproofing is to protect the structure in the toilet and prevent the structure from degradation and deterioration, which will lead to structural damage.

Method, Materials, Procedure, Pros and Cons Of Waterproofing Toilet

a. Epoxy Resin Coating

Epoxy resin coating is a non-hacking method and it is a kind of epoxy resin waterproofing. The epoxy coating can be easily applied without hacking the existing tile. It is a durable coating, anti-slip, and waterproof. During the application, 2 layers of coating are required. After applying the base coating, flakes can be applied to make the toilet with good appearance. After that, top coating is applied.

Epoxy resin coating contains epoxy resin and polyamine hardener. When two components are mixed, they will react chemically and cross-linking of elements will occur during curing. When the epoxy resin coating is completely cured, the final product is durable and rigid. The procedure of applying the epoxy coating includes:

- Clean the area

- Preparation of area

- Apply base coating

- Apply flake (optional)

- Apply top coating

The pros of epoxy coating are economical, resistant, long service life, and easy to customize. The cost for the epoxy coating is lower compared to the other type of waterproofing. It has good water resistance and durability. In addition, epoxy coating is also easy to customize since it can mix with infinite colours, and it can customize with flake flooring and pattern. The cons of epoxy coating are the smell and preparation work. It has a strong fume and various preparation works needed to be done such as cleaning the area, taping the area, and curing time before starting maintenance.

Figure 1: Epoxy Resin Coating in Toilet

Cementitious waterproofing is a hacking method and it is in a type of cement-based of waterproofing. This type of waterproofing can be easy, and it is a conventional method to provide protection for structure and surfaces, preventing water penetration and waterproofing the structure. Two coatings are needed when applying the cementitious coating. Besides, the additive of acrylic is allowed to create a more durable and solid coating.

The cementitious coating is a powder that consists of sand, organic and inorganic chemicals, and silica-based substances. When lime is added to these ingredients, hydration occurs, which explains the ability of cementitious waterproofing. The procedure of application the cementitious coating includes:

- Cleaning the area

- Applying acid-etched, lightly sand-blasted, or bush-hammered

- Applying the coating to the surface for two coatings

- Coating finishing and starting for tiling

The pros of cementitious waterproof are easy to apply and seamless. The cementitious waterproof can be easily applied, which is just brush it on the cement or concrete floor and it is seamless. The cons are it does not hold up the crack and needs to be done before tiling. Cementitious cannot hold up in the face of cracking, and it will lose its ability if the cracking happens. The application must be completed before tiling so it cannot be used when leakage happens.

Figure 2: Cementitious Waterproofing in Toilet

Bituminous sheet membrane is a bitumen-based waterproofing. There are two types of bituminous sheet membrane, which are hot-applied bituminous sheet membrane and cold-applied bituminous sheet membrane. Normally, bituminous sheet membrane is applied on the rooftop or a large scale surface because of its simple usage.

However, there is one type of bituminous sheet membrane suitable used in the toilet which is self-adhesive membrane sealing membrane (SAM). It is a type of cold-applied bituminous sheet membrane. SAM is a hacking method that contains the technology of elastic foam, which leads to the revolutionary sealing system. The system adopts fleece free impact bonding to prevent the attack from water and dampness. SAM can be glued directly to the wall and floor slab surface without using additional material. Thus, it can save time because there is no curing process. Due to the technology of elastic foam, it is possible to prevent the application from cracking.

The main ingredient of making self-adhesive is bitumen. The function of bitumen is to facilitate the installation on the surface and provide water resistance. The procedure for application of SAM includes:

- Prepare and measure the area of the toilet

- Check the surface adhesion

- Clean the area

- Apply corner pieces

- Apply tape for corners and edges

- Install waterproof plumbing fittings

- Apply membrane on walls

- Correction and finishing

- Apply membrane of the floor for bathroom sealing

- Cut out the shower drain

- Waterproofing finishing and start tiling

The pros of self-adhesive waterproofing system are installation and time saving. The system can be easily installed with specific equipment required which only needs to stick on the surface, and it can directly install tiling without any curing time. The cons are this waterproofing system cannot sustain an extremely high temperature, resulting in a shortened service life.

Figure 3: Self-Adhesive Waterproofing in Toilet

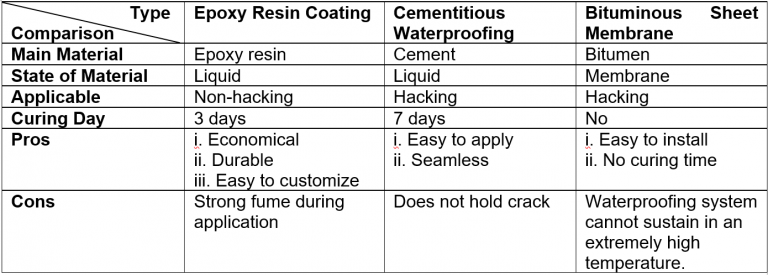

Comparison of Different Waterproofing Methods

Conclusion

In conclusion, waterproofing of toilets is important and inevitable. Due to its function, most of the water leakage comes from toilets. Thus, waterproofing must be done for the toilet before causing serious damage and harm to the structure and people. Several waterproofing applications are available in the market such as epoxy coating, cementitious waterproofing, and SAM. In this era of technology, the implementation of waterproofing methods has become easier and more affordable, especially for toilets which are usually a small area. The owners are suggested to engage the professional contractor for waterproofing the toilet in order to prevent any avoidable damage afterward.

References

[1] Parker, J. (2015). 5 Reasons You Should Have Your Bathroom Waterproofed. Performance Painting Contractors. Retrieved on 14th September 2021 from https://www.performance-painting.com/blog/5-reasons-you-should-have-your-bathroom-waterproofed

[2] JKR. (2014). Standard Specification for Building Works. Jabatan Kerja Raya Malaysia. Retrieved on 14th September 2021 from https://tender.selangor.my/uploads/LmMbUISviqdw2PZs7XxY8PmNGUiOWMZ8ErQwVCON/JKR%20Standard%20Specification%202014_watermark%20(1).pdf

[3] Easy Sanitary Solutions. (2020). [How-to] Waterproofing your bathroom in 10 steps. Easy Drain. Retrieved on 15th September 2021 from https://www.easydrain.com/inspiration/waterproofing-your-shower-and-bathroom/

[4] Technonical. (2020). Self-Adhesive Membrane. Retrieved on 15th September 2021 from https://en.technonicol.eu/upload/iblock/2e4/TN_2017_SA_EN.pdf