Blog

Introduction

Water leakage is a serious problem in every building as it causes the building to become more brittle. Stress develops internally when the water seeps through it, into the interior of the building, thereby reducing the concrete material strength and causes cracking and spalling of concrete. In the worst scenario, the reinforcement bar of concrete will rust as a high presence of moisture and the building structure will eventually collapse. Water leakage can cause certain hygiene problems, such as allergy, irritation of the skin and respiratory system. This is because the fungus growth with moisture present and its spores are a source of allergens and irritants.

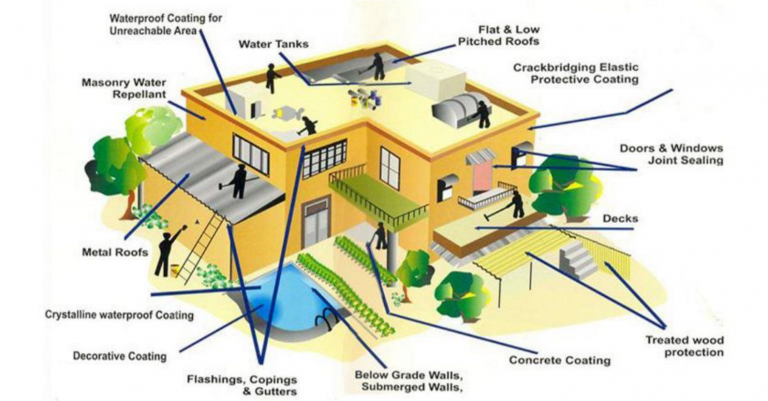

Defects associated with moisture are normal due to defective waterproofing of the house. A well-designed building should avoid water leakage by installing a proper waterproofing system. Figure 1 shows the building elements required for waterproofing [1] . Failure in waterproofing is generally related to the construction design and choice of materials, cracks created, poor workmanship during installation, and water trap in the joints.

Figure 1: Building Elements Required For Waterproofing [1]

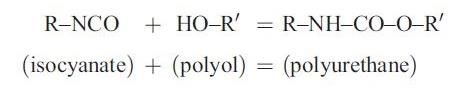

Polyurethane (PU) resin is a long-chain polymer formed by polymerization of isocyanate (-NCO) and polyol (-OH) groups, and it can be either elastic gel or become rigid when reacts with water [2] . Figure 2 illustrates the formation of PU in the chemical formula. PU is good insulation material due to its wide range of chemical and physical properties. It has high expansion characteristic and short reacting period, thus it is an appropriate material for repair water leakage, repair concrete cracks, raising depressed concrete slab or road pavement, resolve settlement problems, etc. PU grouting or injection is a waterproofing solution that uses polyurethane injection expansion to prevent water from running through or splitting in concrete.

Figure 2: Chemical Formula For The Formation Of PU [2]

Benefits of Using PU Injection

The benefits of using PU injection are listed below [3]:

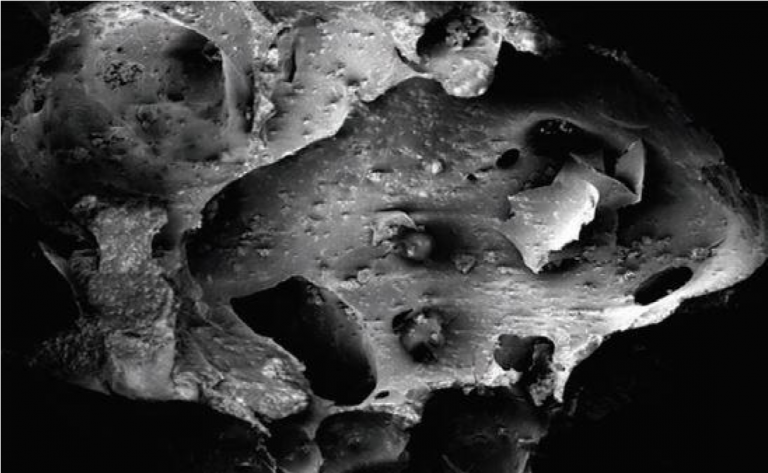

i. High abrasion resistance: It is a solid adhesive that protects the concrete from building movement. The high volume of cross-link (Figure 3) available in its material matrix makes it rigid, strong, and able to withstand abrasion [2].

Figure 3: PU Cross-link Observed Under Electron Microscope

ii. Wide molecular structural variability: PU is a flexible resin that can also be used for paint, maintenance, emergency, and insulation purposes. It also exhibits rigid and expandable when reacting with water and can be used to repair building cracks, raising the depressed structure, solve settlement, and repair water leakage.

iii. Rapid repairing and curing time: It’s fast-drying and can close tiny cracks and voids on the concrete.

iv. Comparatively low cost: PU injection comes with relatively low repairing cost and this approach needs lesser maintenance.

PU Injection

The methods and procedures for PU injection are listed as following [3] [4]:

- Clean the area and decide the location and spacing for PU injection holes (20 – 40 cm).

- Drilling the holes for PU resin injection. The holes should be 45 degrees or less, the depth of drilling should be 2/3 of the thickness of the structure.

- Insert packers (nozzle for PU injection).

- Inject clean water into packers by using a high-pressure pump at 6MPa to clean the dust in the cracks.

- Sealed the visible cracks with cement-based waterproof material to avoid PU grout leak out from the cracks available.

- Inject PU by using high-pressure injection grouting machine. Injection stats at bottom packer and one hole at a time.

- Remove the packers when there is no more leakage.

- Patch up the holes with cement-based waterproof materials.

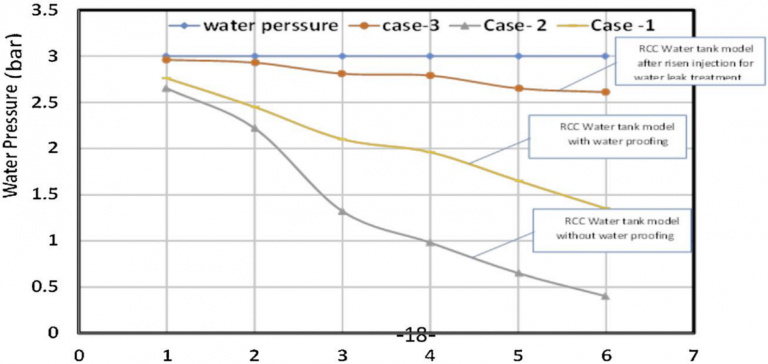

Figure 4 shown the PU injection to repair the water tank crack [4]. which constructed 3 water tank models to investigate the effectiveness of PU injection waterproofing repair. The case study has proven that the water tank repaired by PU injection can significantly reduce water pressure losses compared to the other 2 models (without waterproofing and with flexible water-stops layer as waterproofing system) (Figure 5).

Figure 4: PU Injection To Repair Water Tank Crack [4]

Figure 5: Water Pressure For Each Water Tank Model [4]

Conclusion

Polyurethane resin injection is a good approach to waterproofing repair due to its advantages such as low cost, quick-drying, solid, and high abrasive properties. However, the root cause of waterproofing system failure should be identified to select the best repair methods that fit the financial, material, and safety aspects.

References

[1] Othuman Mydin, Md Azree & Mohd Nawi, Mohd Nasrun & C. Munaaim, M. Arkam. (2017). Assessment of waterproofing failures in concrete buildings and structures. Malaysian Construction Research Journal. 2. 166-179. Retrieved on 27th March 2021 from https://www.researchgate.net/publication/322920802_Assessment_of_waterproofing_failures_in_concrete_buildings_and_struc tures

[2] Jais, I.. (2017). Rapid remediation using polyurethane foam/resin grout in Malaysia. Geotechnical Research. 4. 1-11. Retrieved on 26th March 2021 from https://www.icevirtuallibrary.com/doi/10.1680/jgere.17.00003

[3] M3 Multiservices Pte Ltd (2021). 5 Things About PU Injection Grouting. Retrieved on 26th March 2021 from https://www.m3m.com.sg/pu-injection-pu-grouting-pu-waterproofing/

4] Saafan, Mohamed & Etman, Zeinab & Konswa, Alaa. (2019). Evaluation of Polyurethane Resin Injection for Concrete Leak Repair. Case Studies in Construction Materials. 11. e00307. Retrieved at 28th March 2021 from https://www.researchgate.net/publication/337138007_Evaluation_of_Polyurethane_Resin_Injection_for_Concrete_Leak_Repair

Categories

Archives

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020